《免電風扇》使用手冊,民國6年,作者:Wm. J·H·斯特朗《Black Water Museum Collections | 黑水博物館館藏》

- P C

- 2023年7月16日

- 讀畢需時 12 分鐘

《Non-Electric Fans》Directions 1917 by Wm. J. H. Strong

《免電風扇》使用手冊,民國6年,作者:Wm. J·H·斯特朗《Black Water Museum Collections | 黑水博物館館藏》

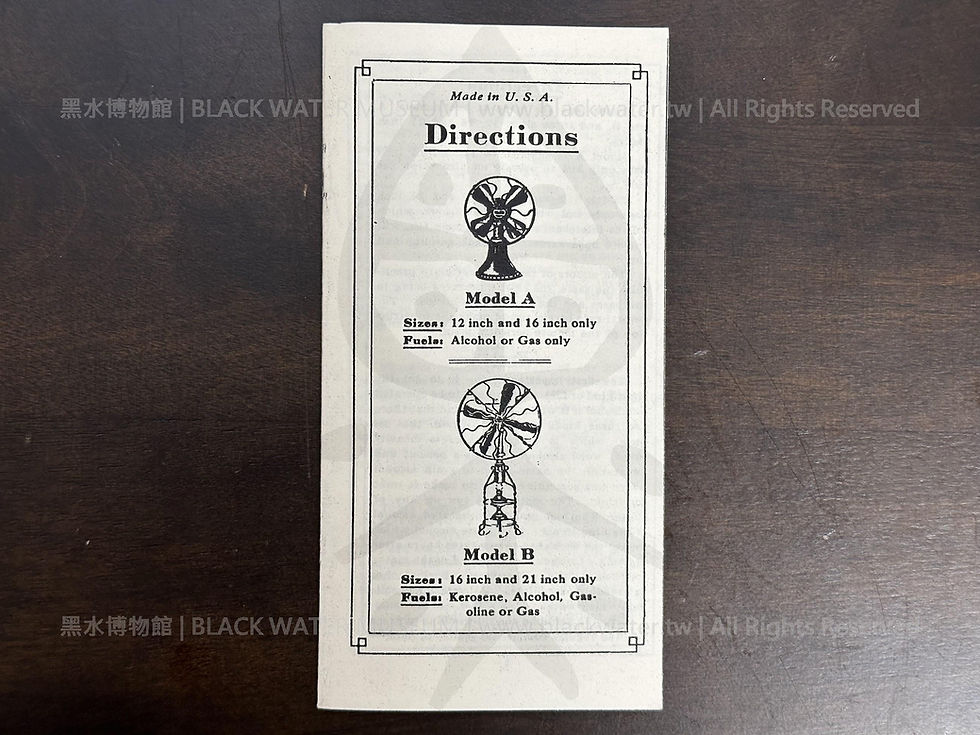

Made in U. S. A.

Directions

Model A

Size: 12 inch and 16 inch only

Fuels: Alcohol or Gas only

Model B

Sizes: 16 inch and 21 inch only

Fuels: Kerosene, Alcohol, Gas- oline or Gas

Directions

These fans are made in two models, A and B, and three sizes. 12, 16 and 21 inch blades.

Model A is supplied in 12 and 16 inch sizes only and to operate on alcohol or gas only.

Model B is supplied in 16 and 21 inch sizes only and with suitable burners, which will fit interchangeably in the same fan, will operate upon kerosene, alcohol, gasoline and gas.

The motors of the two models are practi- cally the same, the chief differences being in the bases and the sizes of the blades. The several cuts herein should make the construction of the motors perfectly plain.

Fuel

The first important thing is to get the right kind of fuel. If the fan is to be operated on alcohol it is well to bear in mind that there are three kinds of alcohol: Grain, that is, pure, which is expensive because heavily taxed; wood alcohol, which is a poison; and denatured, the name given to grain alcohol which has something added to make it unfit to drink. The motor will run on any of these. The best grade of denatured alcohol is the kind to use. Do not use alcohol which makes the wick char two or three hours after starting. On such fuel the speed of the motor will be one-third below normal. Such alcohol is probably over-diluted with water or chemi- cals which weaken it as a fuel.

For the kerosene and the gasoline burners use the regular commercial grades of fuel.

The gas burner is adapted for use with city, natural, Pintsch or Blau gas but not for acetylene.

Oiling

Oil the piston and the plunger rod which passes through the piston with not more than one drop of thin, clean oil each day as dirt in the cylinder or too much oil will stop the engine. The roller bearings may be oiled as freely as necessary but require little oil. No surplus oil from them must be allowed to run down into the cylinder. The piston and the piston stem of the gas fans need a trifle more oil than when the fans are run on other fuels as the gas flame is hotter. Too much oil, however, will get stale and may throw off an unpleasant odor. A bottle of oil with dropping wire attached to the cork is sup- plied free with each fan.

Odor

There is positively no odor of any kind from these fans when they are treated ac- cording to these directions. For the first day or so after the fan is started there is a "new" smell like that of a new stove when it is first used but this soon wears away as the iron and the enamel become thoroughly baked and the fan becomes seasoned.

Speed

These motors run faster on a small amount of fuel burned in the open air than any motor heretofore built. In other words they are the most efficient motors of the type ever constructed. Please bear this in mind. Speed is a question of fuel. These fans can be made to run faster but they would require so much fuel as to render them impracticable. Used according to these directions and within the range of their power, they give

universal satisfaction to reasonable and in- telligent people. Our claim is: Placed 6 or 8 feet from you they will keep you work- ingly comfortable in sultry weather and 10 or 12 feet from your bed will give you restful slumber in the hottest nights. It is remark- able that they run as they do on the small quantity of fuel used.

In case these directions have not been carefully observed, and there is a noticeable slowing down of the motor it may be found due to one or more of the following reasons:

One or more of the bearings are too tight. Superfluous oil below the piston.

Foul wick.

A low grade of fuel, lacking proper heat units.

A lack of piston lubrication.

The inside of the cylinder below the piston must positively be free from oil to get the best speed. A parched surface gives the best results. The piston and the cylinder may look dry from above but still the lower inside walls be coated with oil from previous super- fluous oiling. The directions call for one drop of oil at a time on the piston stem and the piston and it is important not to use more. It is also advisable not to oil the roller bearings too freely for superfluous oil there might run down into the cylinder.

Too much oil in the cylinder can be remedied only by taking the motor apart and thoroughly cleaning and drying out the inside of the cylinder by heating the lower end of the cylinder over the flame. Tie a string tightly around the throat of the casing and then unscrew the four brass screws holding the casing to the cylinder. This will permit the separation of the entire mechanism from the cylinder but one will have to pull hard enough to overcome the vacuum caused by the closeness of the fit of the piston in the cylinder. The string holds all the upper parts together so that they can be put back into the cylinder again easily. The piston fits so closely in the cylinder that even fine lint from a cloth will prevent free action so in replacing the cylinder do not use force to crowd it in except enough to overcome the pressure of the air in the cylinder. Heat applied under the cylinder when the piston is thus removed will dry out the oil and the heat should be left on till no smoke comes. out of the upper end of the cylinder. Washing with gasoline is not enough. Re-oil before starting the motor again.

A foul wick will not permit the fuel to feed freely and therefore the heat of the flame is reduced and the motor will not operate because of a lack of sufficient heat. The remedy for this is to cut off the charred sec- tion of the wick, or if the wick is too old, to use a new one. When the trouble arises from a low grade of alcohol it is hard to remedy as the local dealer who sells the alcohol is usually not to blame. For the most part the alcohol supplied, however, is of a sufficiently good grade.

The natural inclination of the user of the motor is to flood the piston with oil and that. is why we have so carefully emphasized the small amount to be used. Do not neglect, however, to oil the motor once a day as plainly stated for if it gets too dry the friction will slow the speed. In the use of the gas burner the flame must not be burned too high as the heat of this flame is very intense. Should the blades refuse to move it is due to the piston sticking in the cylinder from lack of oil. Gas is so much hotter than the other fuels that it dries out the oil faster. There should only be one person who does the oiling, for if everybody puts in a drop a day there will too much oil accumulate.

This adjustable roller bearing is very ingenious, entirely new and is patented.

If the bearings need adjustment loosen the locknut with the little locknut wrench sup- plied free with each motor. The head of the screw should be held by the screw driver, also supplied free with each motor, while the locknut is being loosened. After the lock- nut is loose the screw may be turned by the screw driver. After the adjustment is made tighten up the locknut again. Roller bear- ing (1) is the power bearing. It performs the heaviest duty and should be kept slightly tighter than the others. Whether the bear- ings need tightening can be judged by the sound of the motor in operation and by its speed, or by the looseness of the bearings to the touch.

Never take the bearings off from the crank shaft without first loosening the locknut and taking out the screw as otherwise the face of the wheels may be seriously marred.

Model A

To start the Model A alcohol motor, grasp with one hand the handle at the top of the fan and tip or rock the fan back on the rear edge of the base, at the same time pressing together the two thumb holds at the bottom edge of base. The fuel tank will drop out. Remove the cap, unscrew the wick holder and fill the tank nearly full of alcohol. Never attempt to use in the alcohol tank any other kind of fuel than alcohol. Adjust the wick so it stands not more than one-sixteenth of an inch above the edge of the wick tube. The total height of the flame itself should not be over one and one-half inches at the most. A flame larger than this wastes fuel. The flame. of the proper size burns less than one ounce. of alcohol an hour and the motor should run at least 24 hours on one filling of the fuel tank. Set the fan back over the fuel tank and it will automatically be locked back in place. After the flame has been applied for a few moments, a slight twist of the brass pulley at the end of the shaft opposite the blades will set the fan in motion. Should the piston stick, due perhaps to dried oil or to dust getting into the oylinder, take off the top of the casing and gently tap the piston with a piece of wood. There is no water about the motor and nothing to freeze.

When the fan is to be stopped, lift it up in the manner previously explained, put out the flame and cover it at once with the cap, and keep the wick covered thus when not in use. as otherwise the wick will gum up and may burn with a slight odor. The vent hole, either gauze or a small tube close to the wick tube, should always be kept clean. In clean- ing the gauze use a small soft brush and do not break out the gauze. If you see the vent is not fully open, or if the gauze becomes the least damaged, send in for a new wick tube. Never let the flame burn when the fan blades are not in motion.

To light Model A when used as a gas burn- er it is only necessary to turn on the gas and to hold a match at the lower end of the flutes in the base.

The burner will light without lifting the fan.

Model B

This Model is always shipped "knocked down," by express or freight only, and must be assembled. To assemble the Model B Fan attach the upper end of the legs to the flange of the cylinder first. Then insert the screws which hold the retainer; then the higher ring, and finally the last or lower ring which holds the auxiliary feet. The stand will go together easily in this manner, but on the contrary if you begin to put it together at the lower end first it will be more difficult to in- sert the screws at the cylinder end.

As you will see there are two kinds of clasps: one is at the bottom of the stand and holds interchangeably the gasoline, gas and kerosene burners; longer spring clasps are attached to the ring near the top and hold the alcohol burner. If the fan is not used as an alcohol burner, of course, the springs are omitted.

With the alcohol or the gasoline burner it is necessary to use the extension sleeve which is put upon the lower end of the re- tainer, or that part to which the legs are at- tached and which encircles the lower end of the cylinder. This sleeve protects the flame from the air currents and prevents the dilu- tion of the heat so that the fan will operate more rapidly with the use of the sleeve than if it is omitted.

Kerosene Lamp

In using the kerosene lamp loosen the ad- justable lamp brackets at the lower ring of the base stand by turning the small wing nuts, insert the lamp already lighted, tighten the wing nuts and it will be held solidly in place. The lamp should not be left burning with the blades stopped. To put the lamp out turn the wick down as far as possible by turning the knurled thumb screw or other wick elevating or lowering device on the side of the top of the lamp bowl.

The kerosene lamp will not throw off the slightest odor if properly cared for. After filling be very sure to wipe off the font care- fully with a dry cloth. Let the wick remain turned down as far as possible. Start the flame low and after the lamp has been burn- ing awhile the wick may be gradually turned up. If turned too high the lamp will smoke. When putting the flame out turn the wick down as far as possible. Never attempt to trim the wick by cutting. When it needs trimming take out the spreader from the cen- ter of the wick, turn up the wick a trifle and with a circular motion from right to left, in ether words opposite to the motion of the hands of a clock, wipe off the top edge of the wick with a piece of paper. If the wick is left up when the lamp is not in use the oil creeps up by capillary attraction and the more volatile portions evaporate leaving the heavier oil and it is this oil residue which makes the lamp smell, but if the wick is kept turned completely down, as directed when the lamp is not in use and the surplus oil wiped off after filling, the lamp will burn without odor. As before stated when the fan is new there is a slight odor for a day or two until the iron and the paint become thoroughly baked.

Chimneys

The kerosene lamp requires a special chimney. Nothing must be placed around the lamp, which will reflect the heat back on it or impede the circulation of air, as the hotter the lamp gets the faster the oil will flow in the wick and the lamp will smoke. Two chimneys and two extra wicks are supplied free with each lamp.

Black chimneys can be supplied if desired. for night use. They must be handled care- fully as they are somewhat fragile and they do not allow the flame to be turned high or the heat will be reflected on the burner and the lamp will smoke.

Gasoline Burner

The Gasoline Burner is a specially made blow torch. The tank will stand a very high pressure, but it operates most successfully on a lower pressure.

It is very important that in screwing the burner tube onto the tank, the screw threads should first be soaped with common brown soap. The soap makes the connection air tight.

To operate, unscrew the outer plug on the side of the tank, fill it nearly full of gasoline, and then screw in the plug so that it is air- tight.

Pe sure to have the valve at the top of

the tank, the one with the long stem, closed tight. To start the burner it is necessary to put

a slight air pressure in the tank and then to

heat the burner tube stem.

To apply the air pressure open the auto- matic air check valve by turning the upper screw plug in the large filler plug on the side. Then put the tip end of the air pump in the air hole, give not more than one small stroke of the pump and then screw up the air valve again. This puts a slight air pressure in the tank.

The asbestos torch is then saturated with alcohol and attached around the tube above the valve. After it has burned a short time the long stem of the valve is opened and if the tube is heated sufficiently and there is not too much air pressure the Bunsen burner will light by a match held at the top of the burner tube. A little experimenting with this will indicate to you its method of opera- tion. After the gasoline burner has been An air pump, running a short time one or two more strokes of the air pump are necessary. a torch and a wrench are supplied free with each gasoline burner.

If the burner orifice plugs up turn in either direction the wire handle of the tip cleaner at the base of the burner tube. This operates the tip cleaner which keeps the very fine burner hole clean. This is made clear by the cut herein..

Alcohol Tank

The manner in which the alcohol font is used in Model A fans is shown in the cuts. The alcohol tank for Model B is inserted in the upper removable springs, or clips, which hold it solidly in place. These springs are of tempered steel and are not supplied with the Model B fan unless the alcohol font is ordered. The Model B alcohol tank also requires a flame protector not necessary for the Model A.

Keep the wick covered with the cap when the fan is not in use.

Gas Burner

The cut indicates how the gas burner is used with Model A fans.

The gas burner for Model B is inserted on the lower clamps and to light it the match is placed where the gas tube enters the re- tainer, If you wish to see the flame hold a small looking glass just below where the tube enters the retainer, with the glass flat and facing up. The flame will be clearly reflected in the glass and if the air holes at the base of the burner are properly open you will note that it makes a cone shape with a decided point. This cone should not be more than 1/2 inch high and the point of the cone should just touch the bottom of the brass cylinder.

The slit near the air holes at the bottom of the burner tube. which admits the gas, is adjusted before leaving the factory for Chi- cago city gas containing 660 heat units. per 1000 cubic feet and at 4 ounce pressure.

Comments